Browsing the Globe of Fasteners and Machining: Techniques for Accuracy and Speed

In the complex realm of bolts and machining, the pursuit for precision and speed is a perpetual difficulty that demands thorough interest to information and calculated planning. From recognizing the varied range of bolt kinds to choosing optimum materials that can withstand strenuous demands, each action in the procedure plays a pivotal duty in accomplishing the wanted outcome. Accuracy machining methods additionally elevate the intricacy of this craft, calling for a fragile balance between technical experience and cutting-edge methods. As we explore the methods that can improve both speed and performance in this domain name, the interaction in between quality assurance procedures and functional quality becomes a vital focal point.

Understanding Fastener Types

When selecting fasteners for a task, comprehending the various types available is crucial for making sure optimum performance and integrity. Screws are used with nuts to hold products together, while screws are flexible fasteners that can be made use of with or without a nut, depending on the application. Washers are crucial for distributing the tons of the bolt and protecting against damages to the product being fastened.

Picking the Right Materials

Understanding the importance of selecting the right products is paramount in making certain the ideal performance and integrity of the chosen bolt types discussed formerly. When it comes to fasteners and machining applications, the product option plays an important function in establishing the total stamina, resilience, deterioration resistance, and compatibility with the intended environment. Various materials offer differing buildings that can significantly impact the efficiency of the bolts.

Common materials utilized for bolts include steel, stainless-steel, aluminum, titanium, and brass, each having its unique staminas and weak points. Steel is renowned for its high toughness and sturdiness, making it appropriate for a large range of applications. Stainless steel provides exceptional corrosion resistance, ideal for settings susceptible to moisture and chemicals. Aluminum is corrosion-resistant and light-weight, making it ideal for applications where weight reduction is important. Brass is commonly selected for its aesthetic charm and excellent conductivity. Titanium is recognized for its remarkable strength-to-weight proportion, making it perfect for high-performance applications. Selecting the best product entails considering elements such as strength requirements, environmental conditions, and budget plan restrictions to make certain the desired efficiency and long life of the bolts.

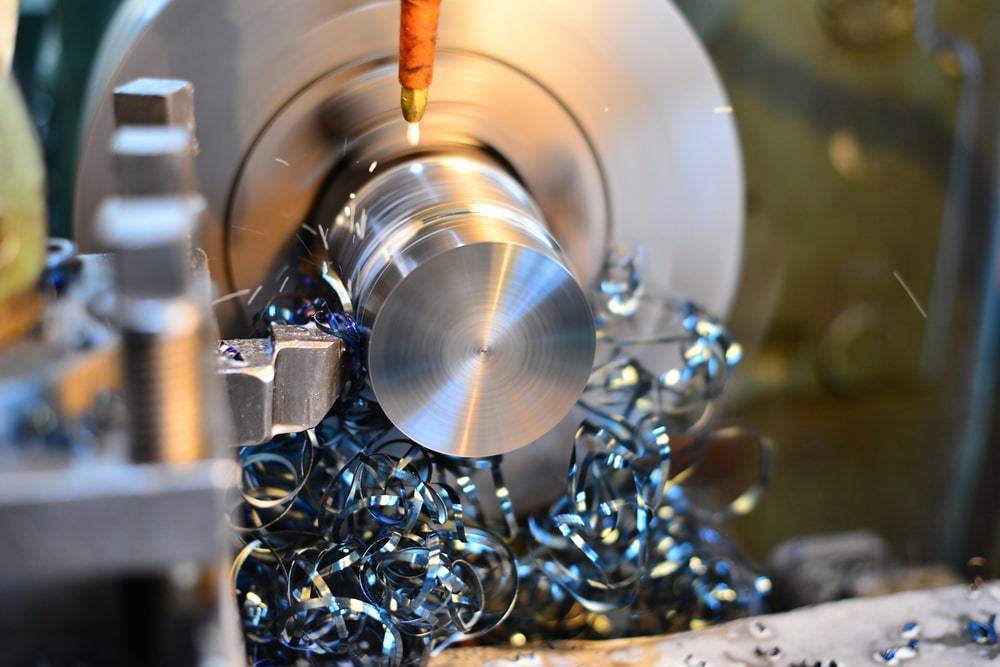

Precision Machining Techniques

In enhancement to CNC machining, various other precision methods you can check here like grinding, transforming, milling, and exploration play essential roles in fastener production. Grinding aids achieve great surface coatings and limited dimensional tolerances, while transforming is usually used to create round parts with precise diameters. Milling and drilling operations are important for shaping and creating holes in fasteners, guaranteeing they fulfill specific specs and feature appropriately.

Enhancing Speed and Efficiency

To enhance bolt production procedures, it is necessary to simplify procedures and implement effective methods that enhance accuracy machining techniques. One crucial technique for improving rate and performance is the application of lean manufacturing principles. By reducing waste and focusing on continual improvement, lean practices assist maximize and remove bottlenecks operations. Additionally, purchasing automation technologies can significantly increase production speed. Automated systems can manage repeated tasks with precision and rate, allowing employees to focus on more complicated and value-added tasks. Adopting Just-In-Time (JIT) supply monitoring can likewise improve performance by making certain that the ideal products are available at the correct time, minimizing excess supply and reducing lead times. Promoting a society of partnership and interaction among team members can enhance general performance by advertising transparency, problem-solving, and advancement. By incorporating these techniques, makers can attain a balance in between rate and accuracy, eventually enhancing their one-upmanship in the bolt sector.

Quality Control Procedures

Implementing strenuous quality control procedures is vital in ensuring the integrity and uniformity of fastener items in the manufacturing process. Quality control actions encompass various stages, beginning with the choice of raw products to the last examination of the finished bolts. One fundamental facet of quality assurance is conducting complete product assessments to validate compliance with specs. This includes analyzing factors such as Continue product structure, longevity, and stamina to guarantee that the bolts meet industry standards. Additionally, monitoring the machining refines is vital to maintain dimensional precision and surface area finish high quality. Making use of sophisticated innovation, such as computerized evaluation systems and accuracy measuring tools, can improve the accuracy and efficiency of top quality control procedures.

Normal calibration of devices and equipment is essential to maintain uniformity in production and make sure that bolts fulfill the necessary tolerances. Implementing strict methods for determining and attending to defects or non-conformities is essential in stopping substandard products from getting in the marketplace. By establishing a comprehensive high quality control structure, suppliers can promote the credibility of their brand and deliver bolts that satisfy the highest standards of efficiency and durability.

Verdict

In the detailed realm of bolts and machining, the mission for precision and rate is a continuous obstacle that requires precise interest to information and calculated planning. When it comes to bolts and machining applications, the material option plays a vital function in establishing the general stamina, sturdiness, rust resistance, and compatibility with the intended environment. Accuracy machining entails different sophisticated methods that ensure the limited resistances and requirements required for fasteners.In enhancement to CNC machining, other precision strategies like grinding, transforming, milling, and drilling play essential duties in fastener production.To maximize fastener production procedures, it is necessary to improve operations and apply effective strategies that enhance precision machining methods.